Mehtamorph

Research and design a more humane way to treat idiopathic scoliosis in children, improving current treatment experience.

A more humane treatment.

Have you ever heard of early-onset scoliosis? it’s a life threatening condition children can suffer from, that curves the spine in every axis. The worst part? doctors don’t know the cause.

Mehtamorph is a 3D-printed corset that treats the condition in a more humane way. Current treatments are really uncomfortable and painful, so the aim of this project is to solve all of these problems, and give kids a chance at a more normal childhood.

6 months

Time spent on project

1 challenge

Design a medical product using HP 3D printing technology.

2 Roles

User Researcher, Designer.

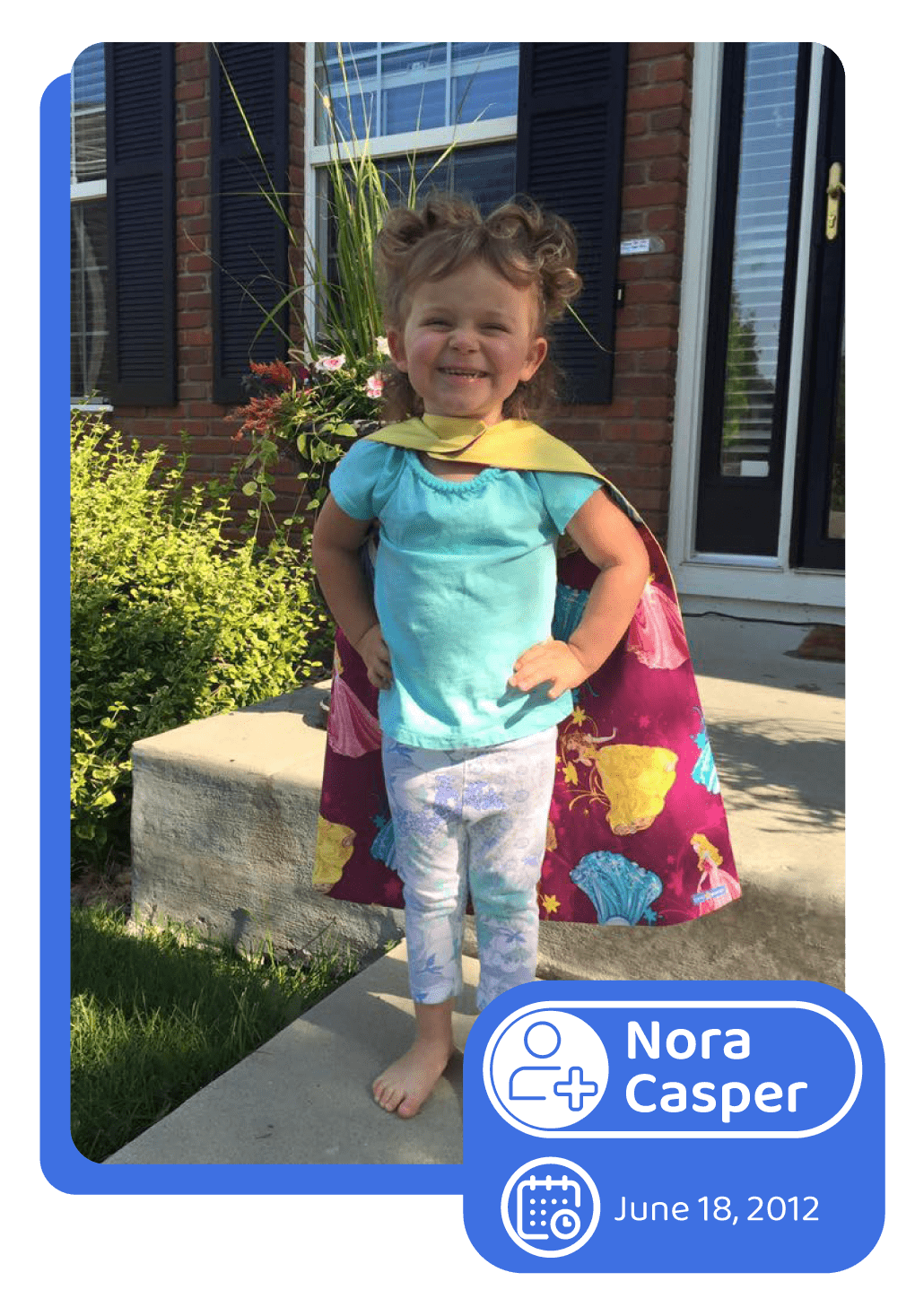

Meet Nora, our little hero.

You can see how proud she is to be wearing that cape! She’s quite the happy toddler. Although, just like any hero, she has a very powerful enemy to fight against.

She suffers from early-onset scoliosis.

It’s a life threatening condition children can suffer from, that curves the spine in every axis. Doctors have no clue what causes it, children are just born with it.

It can cause physical deformity, chronic pain and pulmonary & cardiac complications.

In severe cases, it can be incapacitating, even deadly.

There’s no cure for scoliosis, but it can be managed with treatment.

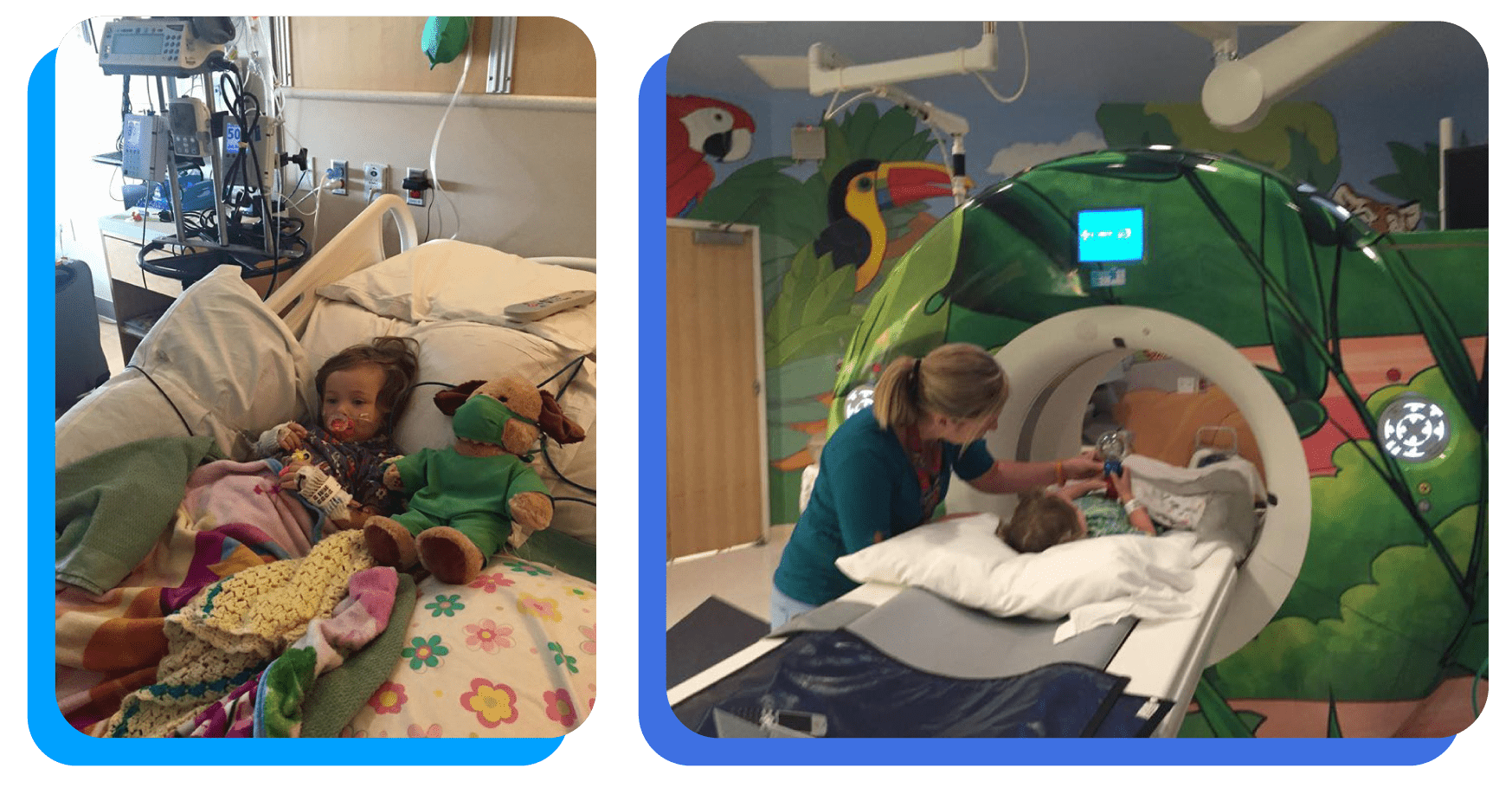

Her case was severe.

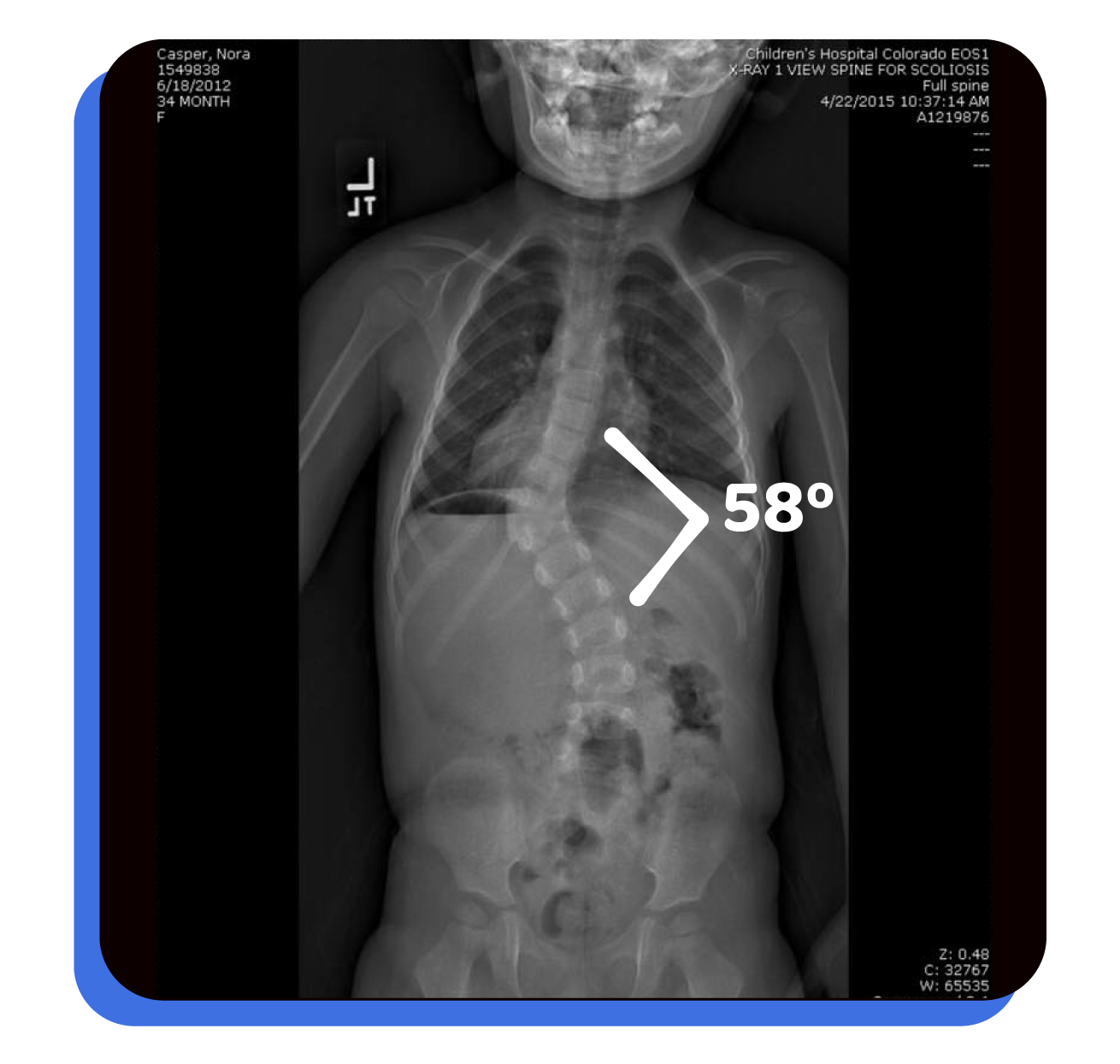

At the time of diagnosis, Nora’s spine exhibited a curvature of 37º, which progressed to 58º in less than a year. The team consulted with spine specialists, traumatologists and pediatricians, who concurred in telling us that if the curvature progressed at a rate higher than 20º per year, (∼2º per month) it’s considered severe and requires medical intervention.

To correct the curvature, her caregivers opted for Mehta casting. It works by encasing the entire torso in a plaster cast. This is the preferred course of action when dealing with this type of scoliosis, but it has several drawbacks. It’s uncomfortable, rigid, it doesn’t allow the skin to breathe, and the cast needs to be changed every 4-6 weeks because of the child’s growth.

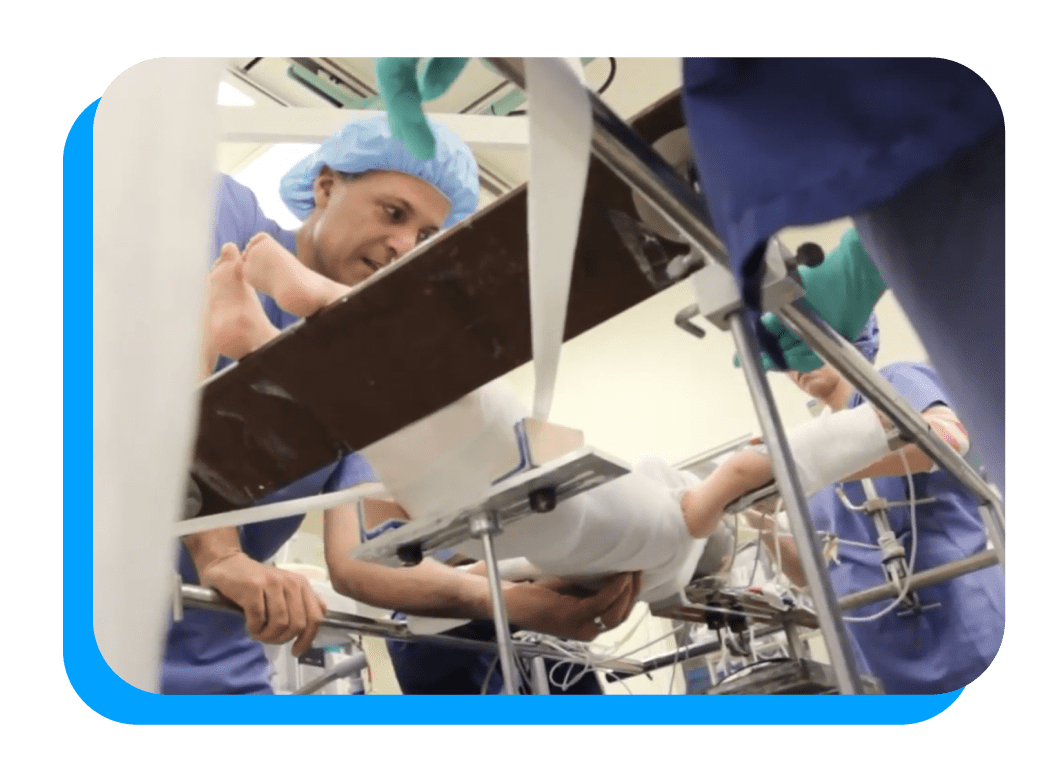

Mehta casts are molded by doctors directly on the child. The child is first put on a special table where they’re only supported by their arms and legs (medical specialists need the entire torso free to mold the cast properly), that allows doctors to twist the kid and their spine into the correct position. The procedure requires general anesthesia.

Once the child is in position, the doctor molds the cast around their torso, generating pressure in specific points to aid the spine’s growth in a more adequate position. Doctors do all this by feel, relying on their expertise and the X-rays taken before the procedure. However, they can’t know if they applied the correct amount of pressure until the cast sets and another X-ray can be taken. Too little pressure, and no spinal correction will happen, too much pressure and the child could have difficulty breathing or pumping blood. Either case would require a new application of the Mehta cast.

We knew that design could offer a better solution to this procedure, so we decided to get to work!

So we set to create Cocoon.

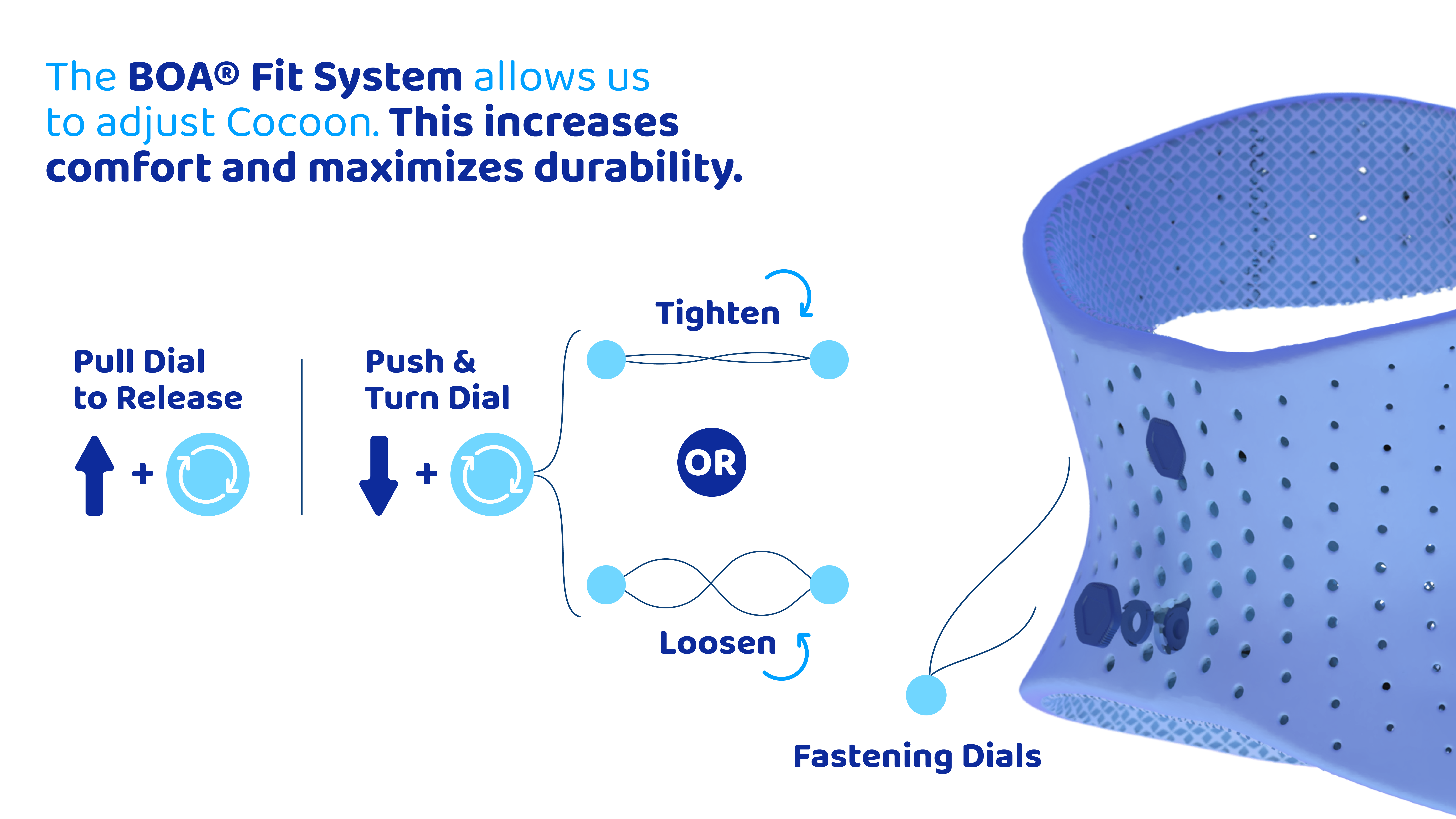

The team got to work, and we designed a cleaner, breathable, more comfortable corset, precisely adapted to the child’s body.

This is also where our name comes into play. Mehtamorph is inspired by the Mehta cast, merged with metamorphosis, the process of transformation.

Following this train of thought, the corset is the kid’s Cocoon, a place where they can develop and grow into their “final form”.

How’s this thing made?

There’s no way we could have made this without additive manufacturing, commonly known as 3D printing. This process gave us the ability to customize every Cocoon to fit every kid and their specific spine curvature precisely.

Just like a doctor molds the plaster around the child’s torso, we can offer the same level of care, fit and precision, without having to put the child under anesthesia.

Our model is entirely constructed in Grasshopper 3D, which allows us to automatically adapt the corset to any child. By introducing a 3D scan of the affected child and defining the required pressure points to correct the spine, the 3D model of the corset adapts to fit the body like a glove, allowing us to offer a perfect fit every single time.

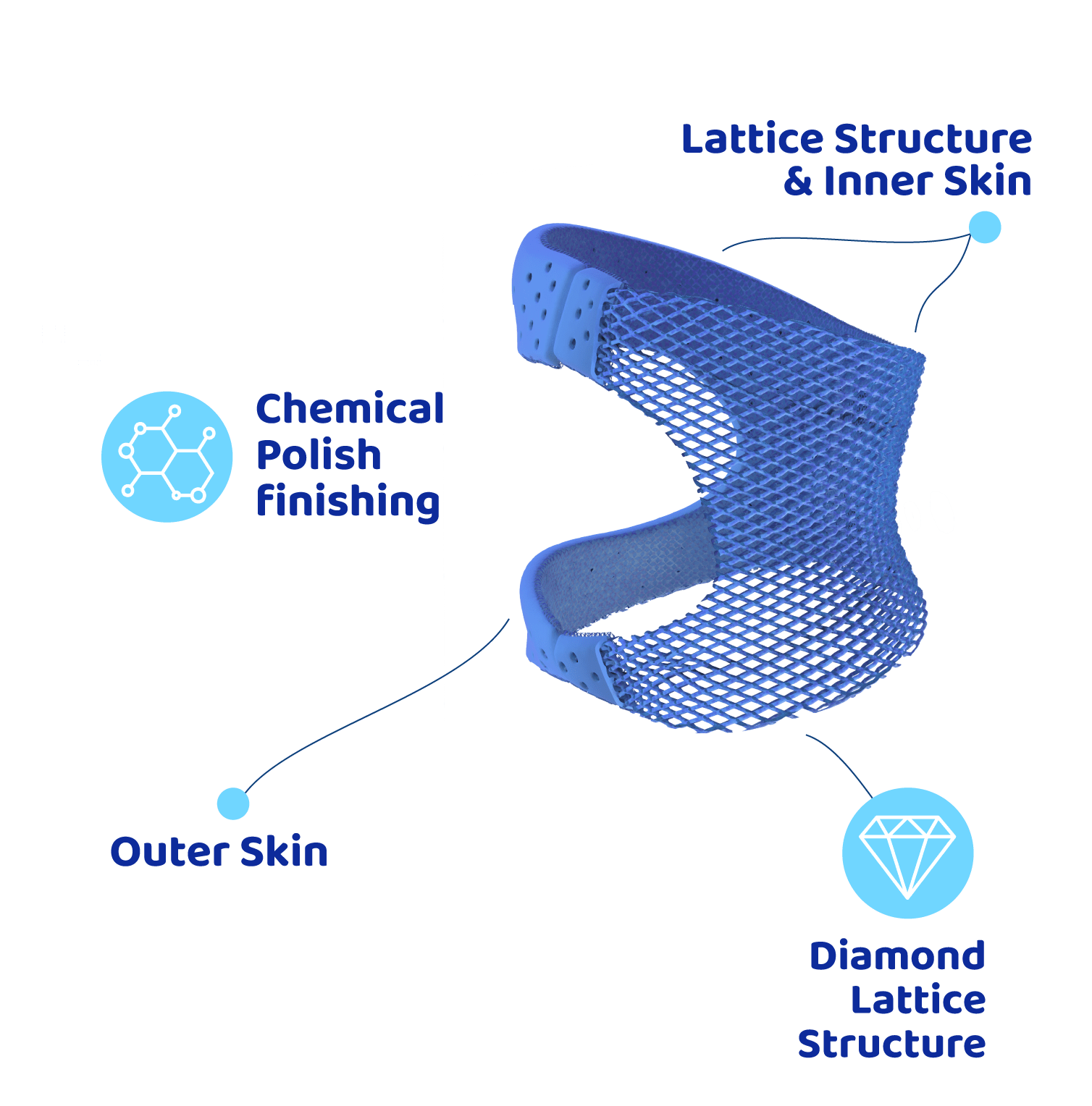

Materials and structure more than just for looks.

The team also thought about the materials and the properties we wanted to have in the corset. We decided on TPU mainly because of the flexibility and skin compatibility.

We gave it a thicker outer skin to protect the structure. It’s tough so that kids can be kids and have fun without having to care for it.

On the inside, there’s a diamond lattice structure. Think of it as your mattress, it’s soft to the touch, but once you lay on it, it provides all the support you need for a good night’s sleep. There’s an inner skin that acts as a buffer between the child and the lattice, making it comfy and stretchy, all while applying the necessary force.

Finally, we applied a chemical polish finishing, which makes the TPU much more resilient while enhancing water resistance.

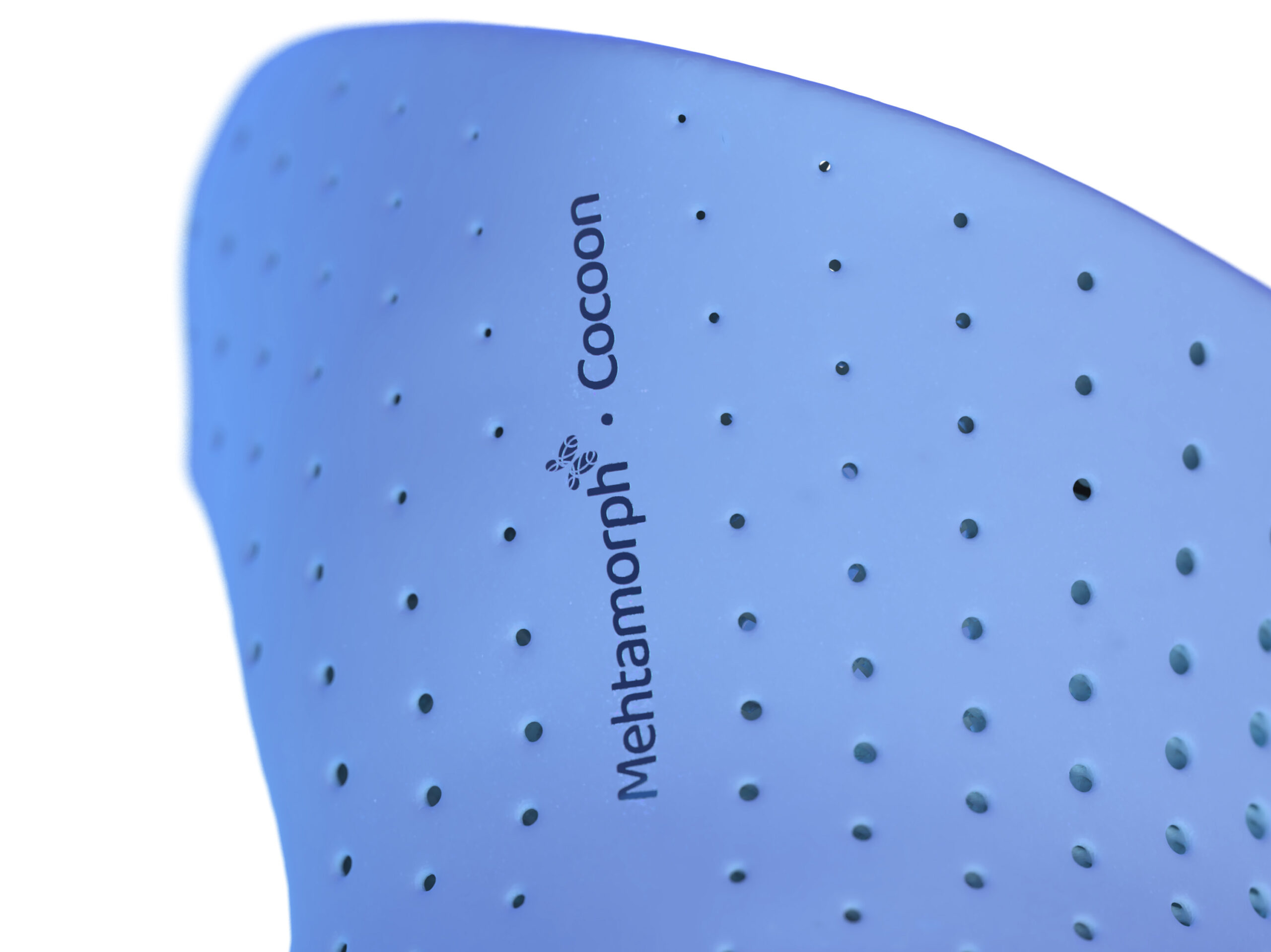

There’s tiny holes all around the corset that allow the skin to breathe better, making it more comfortable for longer periods of use. By doing this, we also waste less material, because we only use what’s really necessary for every Cocoon.

That’s it!

Hope you enjoy it as much as I loved working on it.

Want to get in touch?

RNPDesign.com | My portfolio | All rights reserved. 2024.